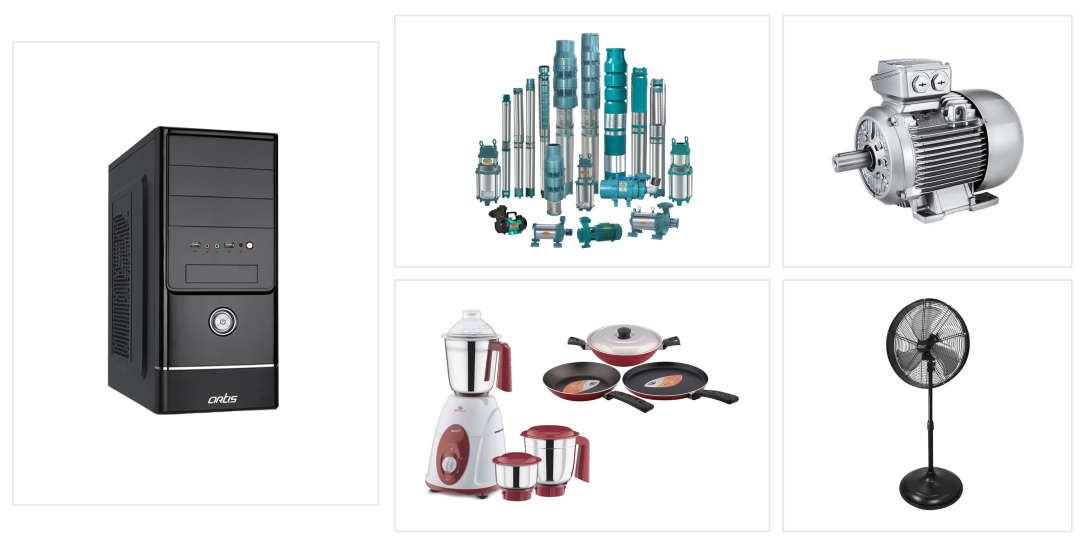

Cold Rolled Lamination/Stamping steel is specifically engineered for high-performance applications requiring precision, durability, and superior surface quality. This material undergoes a meticulous cold rolling process that enhances its mechanical properties, providing exceptional strength, smoothness, and dimensional accuracy. It is widely used in the production of electrical components, such as motor cores, transformers, and other electrical laminations, where efficiency and magnetic properties are crucial. Cold Rolled Lamination/Stamping steel offers excellent formability and can be easily stamped or shaped into intricate designs with minimal distortion, making it ideal for producing detailed components. Its uniform thickness and consistent surface finish ensure reliable performance and optimal fit in high-precision applications. Additionally, the material’s high electrical conductivity and low core loss contribute to improved energy efficiency in electrical devices. Available in various grades and thicknesses, Cold Rolled Lamination/Stamping steel meets the stringent demands of the electrical and automotive industries, delivering both quality and performance in every application.

This ensures better paint adhesion, which in turn helps prevent rust formation on the end applications. the same technology enhances the visual appearance of the finished product. Additionally, with better paint, the aesthetics of the finished product are enhanced.

Cold-rolling technology ensures consistent and excellent properties throughout the coil. This enables customesto achieve the best yield for the desired sizes.

Uniform thickness provided by our state-of-the-art cold rolling mill ensures high yield for customers, Minimal thickness variation leads to consistent performance at compnonent level.

The euipment at our facility ensures absolute flatness of the coil, making the material's performaance more effective during laser cutting. Superior Paint adhesion makes the product aesthetically appealing.